Our Specialties

Articles

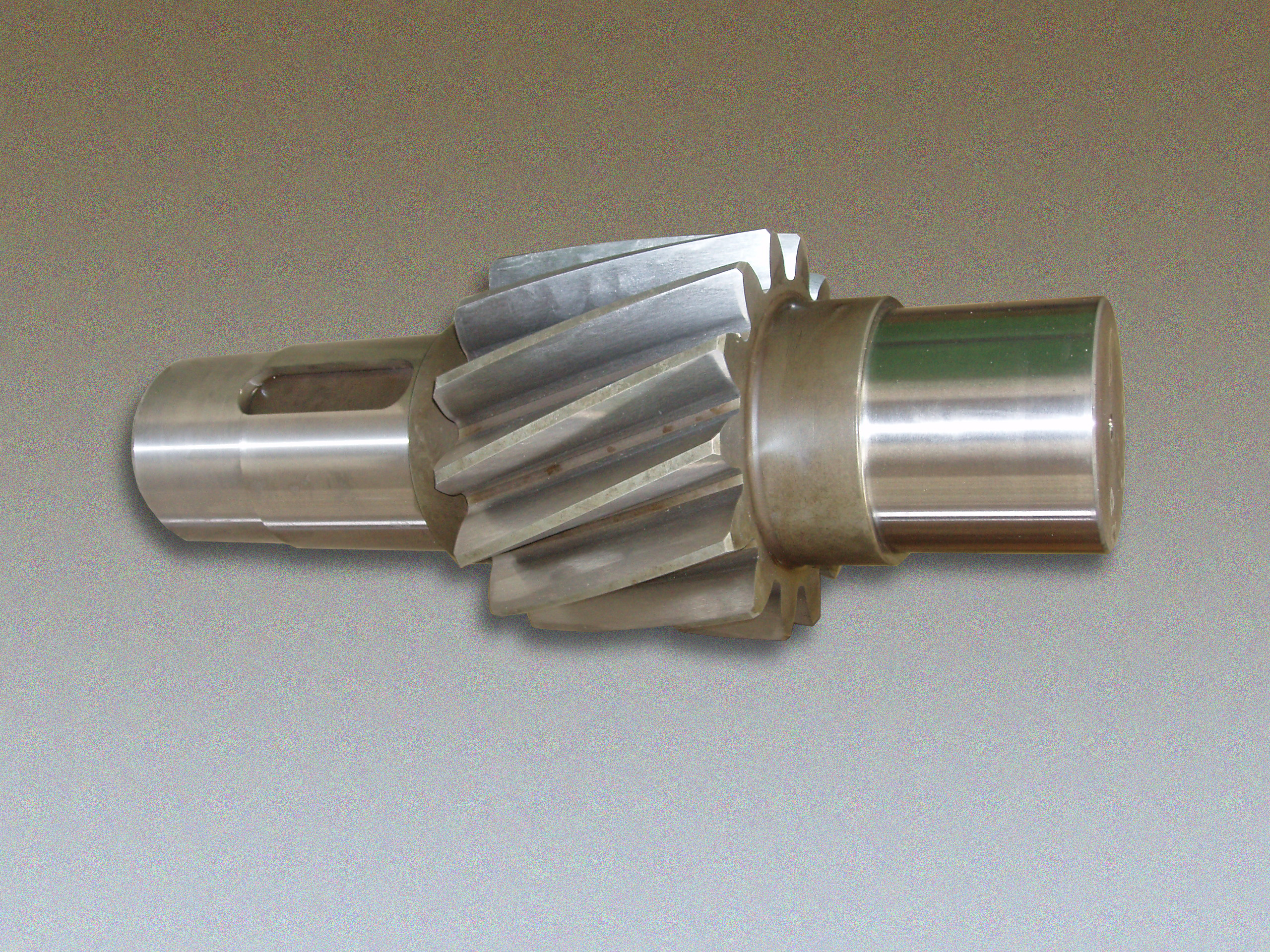

Gear cutting is a machining process used to create gears, which are essential components in many mechanical systems. The process involves shaping the teeth of a gear to ensure smooth engagement and efficient power transmission.

Metal machining is a manufacturing process that involves shaping and cutting metal materials to create precise parts and components. It typically uses machine tools such as lathes, mills, drills, and grinders to remove material from a workpiece.

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by adding material layer by layer based on a digital model. In industry, 3D printing is used for rapid prototyping, custom part production, and complex, low-volume manufacturing.

Here at Cut & Grind, we have refined our skills to service many different industries and types of work.

Click below for a more in depth look at the solutions we can provide!